Let’s step into a world where sustainable meat production meets technological innovation. In this blog, we embark on a captivating exploration of printing meat using cutting-edge 3D bioprinting technology. Join me as we uncover the remarkable benefits this revolutionary technique brings to the table, both in terms of sustainability and animal welfare. The company we researched is called Steakholder Foods Ltd.

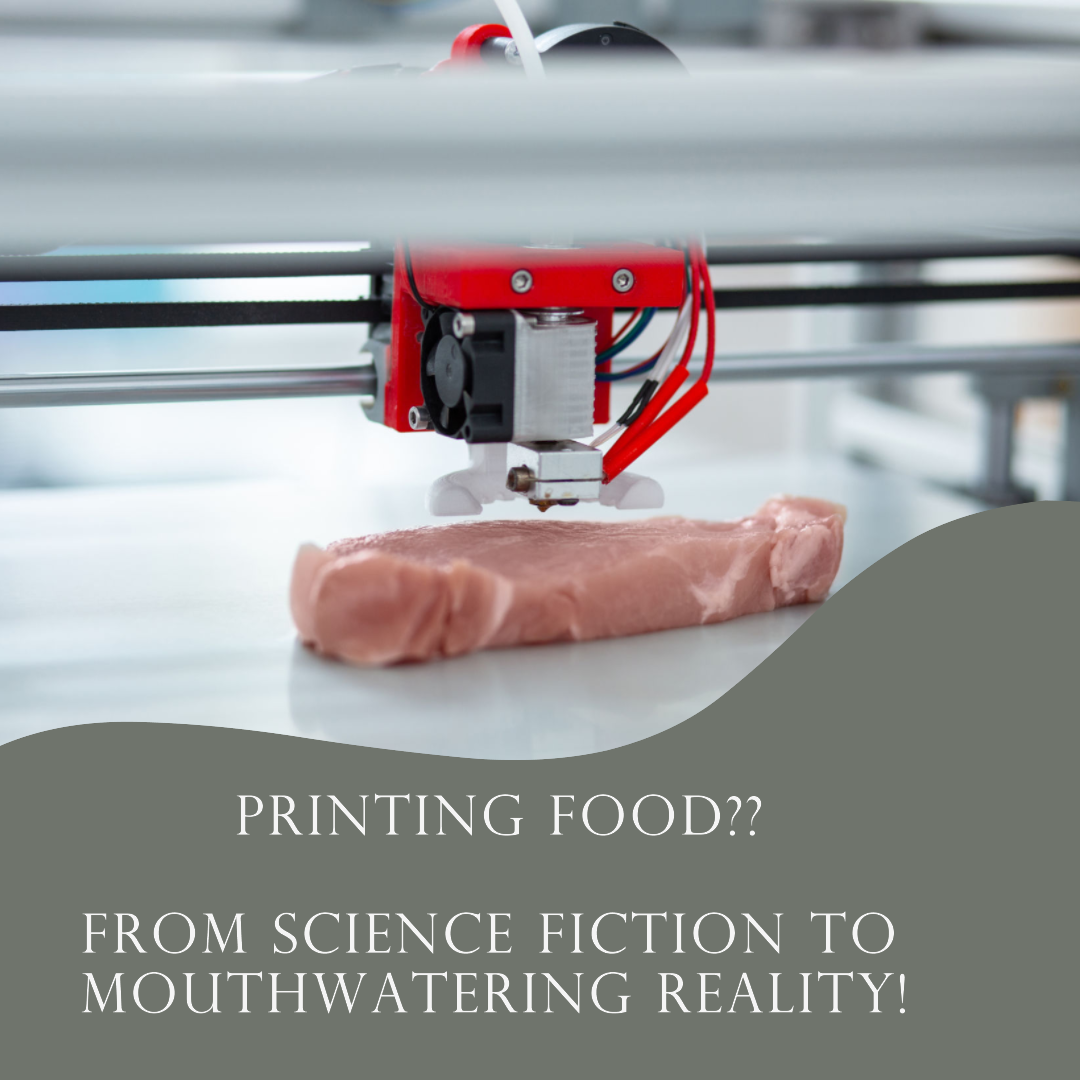

Revolutionizing Meat Production with 3D Bioprinting: In a paradigm shift for the meat industry, 3D bioprinting emerges as a game-changer. Specialized bioprinters, akin to their seafood counterparts, utilize living cells to create tissue and organs. Layer by layer, these printers construct meat by depositing biomaterials like proteins and polysaccharides. This groundbreaking process, known as bioprinting, holds immense potential for personalized cuts of meat that cater to individual preferences. Imagine a real perfect steak every time!

Sustainability and Animal Welfare at the Core: The environmental impact of traditional meat production methods cannot be ignored. With 3D bioprinting, we have a chance to forge a more sustainable path. By reducing reliance on traditional livestock farming, we mitigate the ecological strain caused by land use, water consumption, and greenhouse gas emissions. Moreover, bioprinting presents an opportunity to address animal welfare concerns by eliminating the need for conventional animal farming practices.

Crafting a More Sustainable Future: The benefits of printed meat extend beyond environmental and ethical considerations. Traditional meat production requires substantial resources, including water and feed, leading to inefficiencies and waste. Bioprinting enables meat cultivation in controlled environments with optimized resource utilization, minimizing waste and enhancing sustainability. This technology also has the potential to address food shortages in regions where traditional meat production is challenging.

Overcoming Challenges for a Meaty Future: While printed meat holds great promise, challenges lie ahead. Cost-effective scaling of 3D bioprinting technology remains a priority, as does perfecting large-scale meat cultivation. However, the introduction of 3D printed meat serves as an exciting milestone, propelling us towards a more sustainable and compassionate future in the realm of food production.

Unlocking Sustainable Meat Options: The advent of printed meat expands the possibilities for sustainable protein sources. Customization becomes paramount, offering consumers the ability to tailor their meat choices to align with their preferences and dietary needs. By transitioning from conventional farming to humane bioprinting, we prioritize animal welfare, making strides towards a more compassionate approach to meat production. Ultimately, 3D bioprinting technology has the potential to revolutionize the entire meat industry, offering sustainable alternatives that nourish both people and the planet.

We may have finally created a harmonious fusion of sustainability, technology, and culinary innovation. As 3D bioprinting continues to advance, we can anticipate a future where meat production is more environmentally friendly, ethically conscious, and personalized to individual tastes. Let us celebrate this remarkable progress and embrace the dawn of a new era in meat production—one where sustainability and animal welfare take center stage, bite by printed bite.

We hope you enjoyed this blog and if you are interested in learning more about the food industry please check us out at www.orcainventory.com

Paul Sofsky

CEO

Orca Inventory